Thermal Cover Kurumudan

Simply wrap pipes & tanks to save energy! Reduce loss of production & construction costs by switching from sheet metal processing & racking!

Contents [Hide]

Five effects

Insulation (energy saving)

Heat source equipment continues to radiate heat, so it requires thermal energy even during operation.

Without heat insulation measures, energy will be lost and costs such as utility bills will increase.

Just by attaching Kurumudan to equipment, thermal conduction is blocked and you can take energy-saving measure.

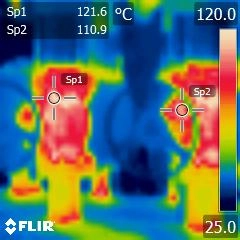

Thermal barrier (prevent heatstroke and burn)

As with insulation, space temperature rise is unavoidable if equipment and piping continue to radiate heat, leading to risk of heat stroke or burns for factory workers.

Wrapping equipment and piping in Kurumudan reduces the amount of heat lost and also helps prevent burn.

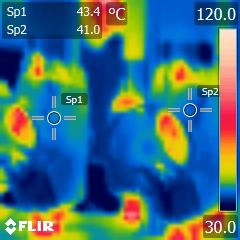

In one case, when Kurumudan was put on a valve with a surface temperature of 120 degrees Celsius, the temperaturedropped to approximately 44 degrees Celsius.

※The heat-shielding effect varies depending on the conditions of use.

※Depending on the thickness of the fabric, Kurumudan can provide even greater thermal barrier effect.

Heat-retention (freezing and condensation prevention)

You need to consider risk of “freezing” in winter when managing production in a factory.

In particular, outdoor pipes can freeze overnight, making it difficult to resume production the next morning.

This could result in a decline in sales across the company.

Kurumudan has a heat-retaining effect and can be used outdoors, so wrapping core equipment like pumps in it helps prevent freezing.

Please contact us if you plan to use the product and it will be exposed to rain.

Safety measure (collision prevention)

A small mistake such as falling in the factory could lead to an unexpected major accident like collide against equipment and getting injured.

Kurumudan is thick enough to retain heat, so it can be expected to provide a safety measure as a cushioning material that softens collisions.

Acoustic insulation (noise control)

If measures are not taken against equipment emits loud operating noises, it could lead to trouble with neighbors or cause health problems for workers.

The Noise Control Act, which aims to protect health, includes a section on “Regulation of noise from factories and workplaces”.

Wrapping equipment in Kurumudan also improves acoustic insulation effect and contributes to noise control.

Five “cans”

You “can” simplify maintenance process

Traditionally, sheet metal processing and work have been essential for heat retention and insulation.

However, the drawback of sheet metal work is requiring the effort and cost of calling a professional for maintenance every time.

Restoring rack is difficult once the insulation material is removed for inspection, and even if it is restored, it looks bad.

Kurumudan is easy to attach, simply fasten with hook-and-loop fastener and string, and can be easily attached and removed without tool.

You can use Kurumudan repeatedly and can decide maintenance schedule.

You “can” use as energy-saving measure

As mentioned before, Kurumudan can be adopted as energy-saving measure easily, cheaply, and immediately.

It also contributes to corporate ESG management, including the SDGs and a carbon-neutral society.

You “can” use as heatstroke measure

As a result of global warming, average temperatures are rising steadily, making measures to prevent heatstroke in factories is unavoidable.

Wrapping equipment in Kurumudan reduces heat loss to the outside of the equipment, so heat-blocking effect can also be expected.

It avoids rise in temperature in the factory and can also be considered as a measure against heatstroke.

We “can” make custom-made products for you

Kurumudan for equipment specified by JIS standards, such as valves and flanges, can be manufactured with only information such as the manufacturer name, model, and bore size.

Therefore, there is no need to conduct on-site inspections when providing an estimate.

In addition to Kurumudan for standard equipment, we can also manufacture custom-made products.

The larger the equipment, the more energy it requires to maintain and restart operations, but Kurumudan can reduce the energy consumption each time.

Click here to check the track record of past support.

You “can” use indoors and outdoors

Kurumudan can be used indoors as well as outdoors.

It can also be used as a freeze protection measure for exposed equipment such as valves, pipes, and pumps that are installed outdoors.

Usage cases

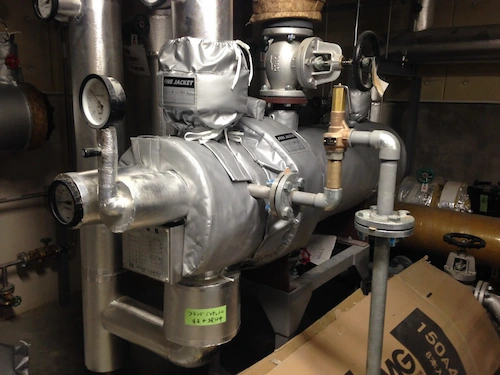

【Diary manufacturer】Plate type sterilizer

【Chemical manufacturer】Glove valve + Y-shaped strainer

An example of insulation for a glove valve and Y-shaped strainer, which are often used in steam piping.

Track records

The lineup listed below is just an example, so if you are considering other equipment, feel free to contact us.

Standard equipment lineup

We can provide estimates for standard products made by various manufacturers without having to visit the site.

Of course, we can also sell just one item.

- Valve

- Glove valve

- Gate valve

- Ball valve

- Reducing valve

- Angle valve

- Safety valve

- Check valve

- Y-shaped strainer

- Flange

- Blind flange

Custom-made products lineup

Measurement of the equipment is generally required, but we can also provide a rough estimate based on drawing or other information.

After you are satisfied with our estimate, we will carry out on-site measurements.

- Sterilizers (plate-type sterilizers [plate-type heat exchangers], tube-type sterilizers [multi-tube heat exchangers], retort sterilizers, etc.)

- Tanks

- Heat exchangers (multi-sensor heat exchangers, plate-type heat exchangers, etc.)

- Pumps

- Furnaces (heating furnaces, drying furnaces, etc.)

- Melt pots

- Robot protectors

- Steam generators

- Extruders (extrusion molding machines)

- U-shaped strainers

- Pipes

- Ducts

Material lineup

By combining various materials, it is possible to keep things hot or cold over a wide range of temperatures.

We will select the most suitable material after inquiring about your usage conditions.

| For steam lines (surface temperature 80 to 200 degrees Celsius) |

For high temperature equipment (surface temperature 80 to 200 degrees Celsius) |

For hot and cold water (surface temperature 0 to 80 degrees Celsius) |

For freezing prevention (surface temperature 0 to 20 degrees Celsius) |

|

|---|---|---|---|---|

| Usage |

|

|

※Capable of coping with outside temperatures down to -5 degrees Celsius |

※Capable of coping with outside temperatures down to -20 degrees Celsius |

| Equipment example |

Valve Piping

|

Drying furnaces Extruder Boiler Exhaust pipe

|

Heat exchangers (air conditioning equipment) Tanks (food plants)

|

Pump (outdoor)

|

| Material lineup |

【Surface and back materials】 【Insulating material】 |

【Surface and back materials】 【Insulating material】 |

【Surface and back materials】 【Insulating material】 |

【Surface and back materials】 【Insulating material】 |

※Kurumudan is most effective when the temperature of the inside of the equipment is 0 degrees Celsius or higher.

When inside the equipment is below zero, Kurumudan may freeze due to condensation.

If you have further questions, please contact us using the inquiry form .

Samples available!

You can try our samples at your site!

If you are interested, please contact us using the inquiry form.

※Kurumudan lineup is extensive, so please choose From the following two types for sample.

- For glove valve 10K-40A

- For flange 10K-65A